Spectrophotometer Cells

Absorption spectrophotometry is based upon the principle that each chemical substance has characteristic properties that determine the wavelengths of radiation it will absorb. Tests are generally made in the ultraviolet, visible and infrared regions of the electromagnetic spectrum. Each different molecular configuration of atoms has unique resonant wavelengths at which energy will be absorbed. When various wavelengths generated by a spectrophotometer are directed into a chemical sample their energy is selectively transferred. This phenomenon of energy transfer is absorption.

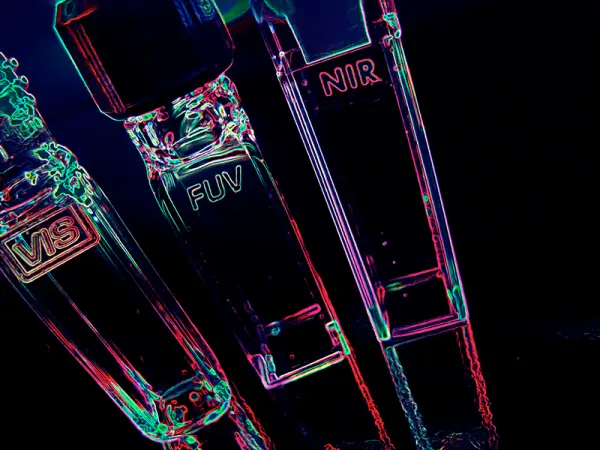

The human eye is only responsive to wavelengths from 390 nanometers (violet) to 770 nanometers (red) of the spectrum. Absorption, however, occurs in the UV and IR regions as well. Spectrocell brand cells are available with VIS, FUV or NIR grade optical windows that will provide excellent results at those wavelengths. See the accompanying charts and tables for the specifications of these various window material choices.

Rectangular Cells are easily the most common type of cell used in any analytical chemistry lab. Because Spectrocell manufactures all our cells to precise tolerances, you are assured our rectangular cells will fit the cell holder provided with virtually any brand of instrument.

While the 10 millimeter light path (3.5 ml capacity) is the most often specified, Spectrocell provides standard light path dimensions from 0.5 mm to 100 mm (see chart) The standard cell window is 1.25 mm thick and we supply rectangular cells with optical windows for VIS, FUV, and NIR range.

Most rectangular cells are provided with a PTFE lid. For better closure, stopper tops are available for most sizes. However, for the ultimate in positive closure, Spectrocell offers a threaded top and PTFE cap – either sealed or septa are available. Our threaded tops have the widest interior opening for easy cleaning compared to other cell companies. We were the first to offer this type of closer. Also available as an option for our rectangular cells is a graded seal, 6 mm x 8 mm tube, and optical coatings on windows.

Cylindrical cells are most often specified when a large volume is desirable or cell volume is not an issue. Cylindrical cells are sometimes required because certain instruments have a large circular beam. Our cylindrical cells are manufactured to the same stringent specifications as all our other cells. Spectrocell offers cylindrical cells in light paths from 0.01 to 100 mm and with window choices for VIS, FUV, and NIR applications. Closure choices are offered as stopper tops or threaded top (solid or septum type caps).

All Spectrocell brand cells are made to configure with industry standards on size and quality. Borosilicate and quartz cells are highly precision optical components and undergo many manufacturing operations, numerous inspections, and procedures to insure conformance to industry standards. All standards in use at Spectrocell are periodically calibrated and all calibrations are traceable to NBS master standards.

With a vast selection of type, size, and material to choose from, you can’t go wrong. All of our cells will fit into most standard size spectrophotometers. For smaller sized path length cells, we offer adapters to hold your cell in the standard 10 mm spectrophotometer. All of our cells are fully fire fused by hand and are produced in our plant in Oreland PA.

Spectrocell standard open top cells are supplied with a Teflon PTFE lid at no extra charge. PTFE Lids offer some containment of volatiles, but are the least reliable closure. Stopper tops are better than lids in containing volatiles. However, they are not completely reliable in that the stopper can be dislodged if the cell tips over, Also, stoppers should never be forced too tightly into the ground taper as the glass or quartz could be fractured. Similarly, never over fill a stopper top cell so that the stopper contacts the liquid: large forces can be generated in this manner which can easily burst any cell. Finally, avoid leaving samples stoppered in the cell for long periods as the stopper may become “frozen” and difficult to remove. Spectrocell stoppers are made of Teflon.

Threaded tops are by far the most effective closure available. Almost complete protection is provided concerning volatiles. Spectrocell pioneered the threaded top cell, was the first to offer such a cell in 1984; and now offers it in a wide variety of choices. Other manufactures have copied the idea, but use a smaller thread size and plastic caps, thereby defeating some of the major advantages of the threaded top concept. Spectrocell threaded tops are approximately 8 mm inside diameter, allowing easy access to the interior for cleaning. Injectable septa caps allow the user to inject substances directly into the cell, minimizing the possibility of exposure, spillage or contamination of the sample or the environment.

- Industry Standard Sizes

- Fully Fire Fused Cells

- Custom Capabilities

- High Quality Threaded Caps

- Deal Directly with Manufacturer- No sales reps

- Made in the USA